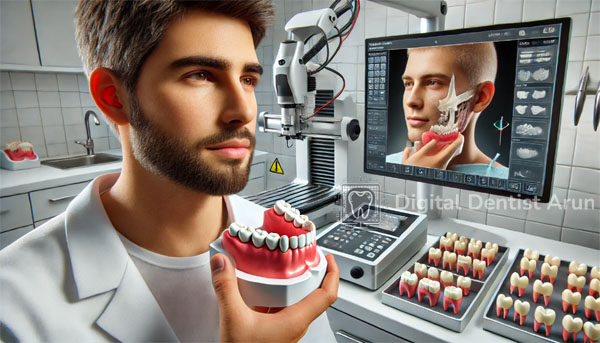

CAD-CAM technology in prosthodontics is defined as the process by which prosthodontic components like crown, bridgeworks, dentures, and implant prostheses are designed and fabricated by Computer-aided design and Computer-aided manufacturing. The process eliminates the manual method of making impressions and fabrication that is done in the laboratory. Compared to traditional techniques CAD-CAM mitigates the errors which leads to better patient outcome, quick reproduction, better quality and detail, and durability in the restoration work.

Process of CAD-CAM Technology in Prosthodontics

The process typically involves three main steps:

- Digital Impressions: An intraoral scanner gives a dentist an ability to take accurate, high definition, three dimensional images of a patient’s teeth and gums without having to take impression.

- Designing the Prosthesis: The digital impressions are forwarded to a software program in which the prosthesis is designed according to the intra oral structure of the patient.

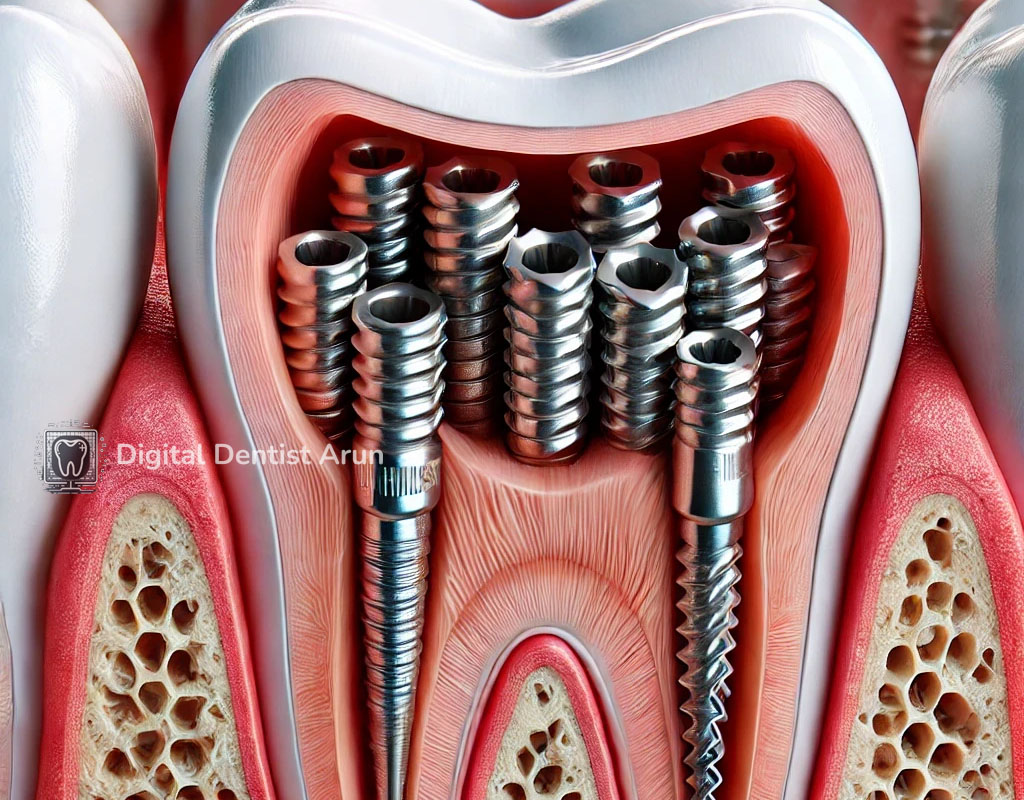

- Manufacturing: The anatomy of the designed prosthesis is produced by using a milling machine where final crown is shaped out of high-quality biomaterials such as zirconia or ceramic. CAD-CAM technology in prosthodontics has also improved the ease of fabrication of accurately individualized prosthetic appliances. This results in more aesthetic appearing restorations as well as better functionality for the particular patient involved.

Benefits of CAD-CAM Technology in Prosthodontics

- Enhanced Accuracy: Digital impressions combined with accurate design software yield better operative prosthetics fit than normal working procedures.

- Faster Production: It can also be done undoubtedly much quicker than the traditional approaches to dentistry, some of the prostheses can be designed and made within a single visit.

- Improved Patient Experience: Patients improve their comfort because such a process does not require using impression materials that cause discomfort to the patient and take a lot of time to prepare.

- Reduced Errors: The process is more efficient and less prone to human error system of restoration.

Application of CAD-CAM Technology in Maxillofacial Prosthetics

Apart from dental restorations, CAD-CAM technology in prosthodontics find extreme application in the rehabilitation of facial defects such as missing eyes, nose or ears because of trauma or congenital abnormalities. CAD-CAM integration in these cases enables the delivery of accurate prosthetic reconstructions that dictate the patient’s aesthetic-behavioral transformation and functionality. The various kinds of three dimensional imaging and the additive manufacturing processes such as 3D printing used in this field is far superior than the time and efforts required to be invested that are entailed in the process of making prosthetics using conventional techniques.

Advances in CAD-CAM Materials

The materials applied in CAD-CAM prostheses have also been enhanced. These materials include, but are not limited to zirconia and lithium disilicate, which demonstrates high strength and esthetics compared to metal and ceramics. This in turn enhances the performance, durability and aesthetics of dental prosthetic restorative treatments. Further, resin-bonded materials are also versatile enabling temporary CAD-CAM restorations and other functions.

Challenges of CAD-CAM Technology in Prosthodontics

Nevertheless there are several issues that can still be discussed as those in the use of CAD-CAM technology in prosthodontics there are some prospects and concerns as well. This largely because of the high costs of purchasing the equipment, and also cost of the maintenance for such equipment’s most especially those that are small in size. Also, the fact that CAD-CAM systems require training for their correct usage means that not all practicing dentists can use the systems well. But if the dissemination of technology services increases, and the cost reduces, the aforementioned challenges are expected to ease.

Future Prospects of CAD-CAM Technology in Prosthodontics

In view of these advancements, CAD CAM technology in prosthodontics will experience further development in the future with the combination of artificially intelligent [AI] to enhance the accuracy of a designed denture and diagnostics. CAD tools for medical applications are on the way and unavailability of patient data to predict outcomes is already addressed by the AI, the future possibilities may include the automated formulation of a plan of treatment and design of a prosthesis.

In the years to come the CAD – CAM technology in prosthodontics is likely to become less expensive and digital dentistry will prevails as the standard of care for restorative treatments.

Conclusion

And through CAD CAM technology in prosthodontics, there is enhancement of the quality of health care in this niche. It is efficient, accurate, speeds up work, and is more comfortable for the patient as it is a useful addition to present-day dentistry. In the future perspectives of CAD CAM in prosthodontics, new AI and materials will enhance the customized treatment for the patient with even better accuracy.

References

Artificial Intelligence In Prosthodontics: New Paradigm Shift. IOSR Journal of Dental and Medical Sciences. Retrieved from IOSR Journals.